Bison Panel

- Home

- /

- Bison Panel

- Bison Panel is basically a multi-purpose Cement Bonded Particle Board (CBPB) manufactured by NCL Industries Limited for first time in India, in Technical Collaboration with BISON WERKE of Germany.

- The Plant has been set up near its Cement Plant in Nalgonda District of Andhra Pradesh during 1992.

- Bison Panel is eco friendly board and does not contain any hazardous material like Asbestos or harmful/strong chemicals. The wood used is of plantation wood and species like Eucalyptus, Poplar etc., thus conserving regular forest wood.

- Bison Panel conforms to BIS Standard IS:14276; CML 1143254

- The Boards Division is an ISO 2000 Certified Company and the Bison Panel conforms to ISO Standards.

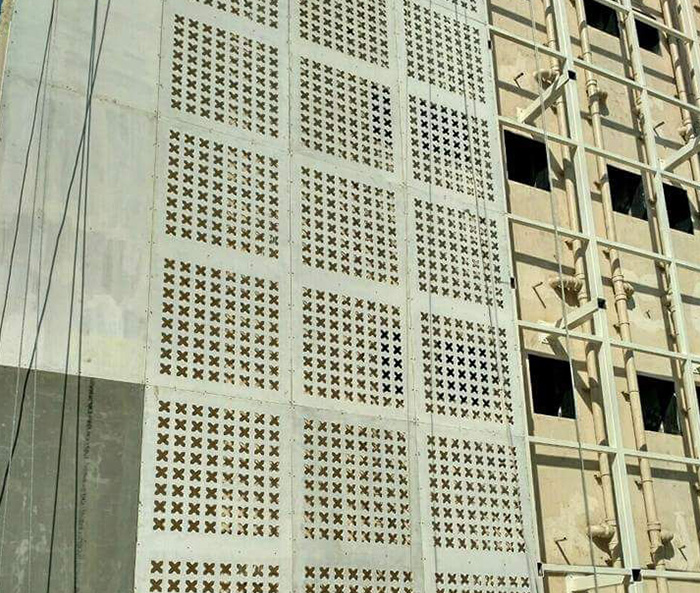

- Bison Panel is the only Cement Board that gives smooth surface on both the sides and can be used for both internal/external applications.

- NCL setup new boards plant with an installed capacity of 50,000 TPA at Himachal Pradesh to cater to the requirements of North & North-East Regions.

- Bison Attributes

- Bison - Exterior Application

- Bison - Interior Application

- Bison - Working With

- Technical Specification

- Gallery

HIGHLY WEATHER RESISTANT: As Cement is the chief material used in the matrix of Bison Panel and twice the wood flakes are mineralized, board is highly durable and best suited for exterior applications.

|

Application

|

PANEL THICKNESS IN MM

|

||||||||

|

6

|

8

|

10

|

12

|

16

|

20

|

30

|

40

|

||

|

Partitions

|

|

|

|

||||||

|

Fire rated partitions

|

|

|

|

|

|||||

|

Wall claddings

|

|||||||||

|

False Ceilings

|

|

|

|||||||

|

Facia Panels

|

|

|

|

||||||

|

Floors

|

|

|

|

||||||

|

Almirah planks

|

|

|

|

||||||

|

Furniture

|

|||||||||

|

Flush doors

|

|

|

|||||||

|

Door Panels

|

|

|

|

||||||

|

Cabins

|

|

|

|||||||

|

Special works

|

|

|

|||||||

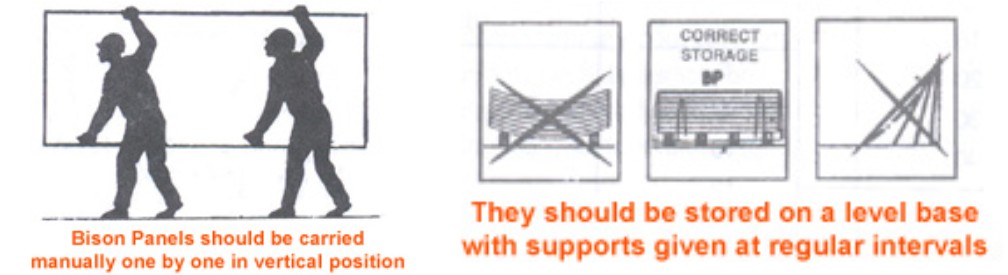

- Working with Bison is like working with any other particle board

- Fastening is done in the same way as any other boards.

- No special tools are required. However for large volumes of cutting work electric hand saw is recommended.

- Similarly hand held electric drill will be faster to work.

Fixing Points

FIXINGM- Bison Panel can be fixed to timber or steel supports. Thin cold rolled steel sections in the form of studs, tracks etc. are available in the market. They can be used with advantage for applications like partitions, false ceilings, flooring etc.

-

SUPPORTS

- In applications, the board should be supported on all four edges and joints. The recommended span between support is 610mm.

|

Thick-ness

|

Edge distance

|

Spacing

|

Inter-mediate

|

|

6-12mm

|

12 to 15mm

|

200mm

|

400mm

|

|

16mm

|

20mm

|

300mm

|

500mm

|

|

20mm

|

20mm

|

400mm

|

600mm

|

|

25mm & above

|

Equal to thickness

|

600mm

|

600mm

|

- Fixing can be done with screws. A pre-hole shall be provided in the Panel before screwing. The length of the screw shall be 2 to 2½ times the thickness of the board.

- The fixing point has to be 15mm (minimum) away from the edge of the board. Similarly the fixing point shall be 40mm away from the corner of the board.

Bison Panel - Cement Bonded Particle Board made in Technical Collaboration with M/s. Bison Werke of Germany - Combines the strength of Cement and workability of wood. Its unique combination of properties gives it all round superiority over most other boards. Its versatility in both internal and external applications is exemplified the world over.

|

|

Transverse Tensile Strength (internal bond) | : | 040N/mm² | ||||||||

|

|

Bending Strength | : | 9N/mm² | ||||||||

|

|

Compressive Strength perpendicular to surface | : | 15N/mm² | ||||||||

|

|

Modules of Elasticity (Bending) | : | 3000N/mm² | ||||||||

|

|

Density | : | 1,250 Kg/mm² | ||||||||

|

|

Thermal Conductivity coefficient | : | 0.22/W/mk | ||||||||

|

|

Sound Insulation | : | Air borne sound reduction varies from 30 dB to 37 dB for various thicknesses for the frequency range 100-3150Hz. | ||||||||

|

|

Surface spread of flame | : | As per B.S. 476 it is classified as Class 'O' building board with Class I surface spread of flame. | ||||||||

|

|

Surface Alkalinity pH | : | Between 11 and 13. | ||||||||

|

|

Screw holding power perpendicular to surface | : | 312 Kgs. | ||||||||

|

|

Nail holding power | : | 205 Kgs. | ||||||||

|

|

Dimensions | : | 1220mm x 2440mm and1220mm x 3050mm | ||||||||

|

|

Thicknesses in mm | : | 6, 8, 10, 12, 16, 20, 25, 30, 40 | ||||||||

|

|

Tolerances in thicknesses | : |

|

Copyright @ Vraj Enterprise All Rights Reserved. Powered By: Pc